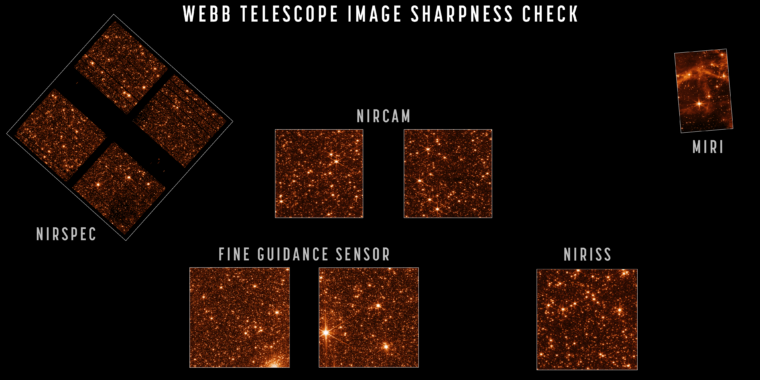

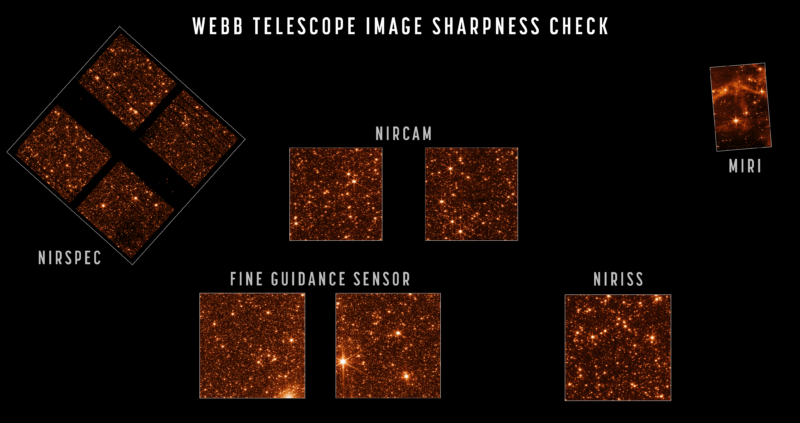

In mid-March, NASA released an image from the Webb Space Telescope showing that the primary mirror reached the point where it focused light as finely as physics would allow for hardware of its size. That was a crucial milestone, but it only applied to one of the five instruments carried by the telescope. On Thursday, NASA announced that the next milestone had been reached: all instruments were now equally sharp in focus.

Webb’s instruments include two spectrographs, two imaging cameras and the fine-guidance sensor that aids in the aiming of the telescope. Each of these had to be individually aligned to the primary mirror to ensure focus, a process that took several weeks. But now the focus for each of them is about as good as physics allows.

That boundary is determined by diffraction, the process by which light interferes with itself and scatters when it reaches an edge or corner. While it is possible to exceed the diffraction limit if you have complete control of the photons and play quantum mechanical tricks with them, it is not the case with telescopes. So diffraction limited is the best we can hope for from a telescope. And according to NASA, it’s slightly better than we had planned: “The telescope’s optical performance continues to outperform the engineering team’s most optimistic predictions.”

But we’re not quite ready to start science yet. Each of Webb’s instruments contains a variety of mechanical hardware, such as filters that block specific wavelengths. This hardware must be checked out to confirm that it is working as planned, a process called instrument commissioning. That process is expected to take about two months, so that science operations can start in mid-June.

In the meantime, NASA will also test the telescope’s cooling systems and validate test/correction procedures to ensure the primary mirror remains properly aligned.