The famous Pantheon in Rome has the world’s largest unreinforced concrete dome – an architectural marvel that has endured for millennia, thanks to the incredible durability of ancient Roman concrete. For decades, scientists have been trying to figure out exactly what makes the material so durable. A new analysis of samples taken from the concrete walls of the Privernum archaeological site near Rome has provided insight into those elusive manufacturing secrets. It appears that the Romans used “hot mixing” with quicklime, among other strategies, that gave the material self-healing functionality, according to a new paper published in the journal Science Advances.

As we reported earlier, ancient Roman concrete, like today’s Portland cement (a basic ingredient of modern concrete), was basically a mix of a semi-liquid mortar and aggregate. Portland cement is usually made by heating limestone and clay (as well as sandstone, ash, chalk and iron) in a kiln. The resulting clinker is then ground into a fine powder, with only a small amount of gypsum added, to achieve a smooth and flat surface. But the aggregate used to make Roman concrete was fist-sized chunks of stone or bricks.

In his treatise The architecture (circa AD 30) the Roman architect and engineer Vitruvius wrote about building concrete walls for tomb structures that could stand for a long time without falling into ruins. He recommended that the walls be at least two feet thick, made of “square red stone or of brick or lava laid in layers.” The aggregate of brick or volcanic rock must be bonded with mortar composed of hydrated lime and porous fragments of glass and crystals from volcanic eruptions (known as volcanic tephra).

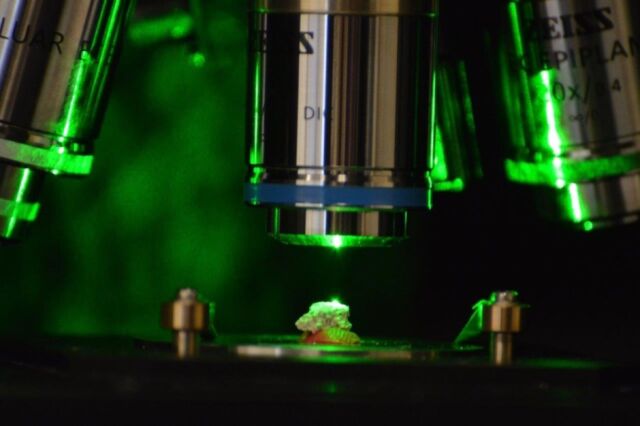

Admir Masic, an environmental engineer at MIT, has spent years studying ancient Roman concrete. For example, in 2019 Masic and two colleagues (Janille Maragh at MIT and James Weaver at Harvard) pioneered a new set of tools for analyzing Roman concrete samples from Privernum at multiple length scales, notably Raman spectroscopy for chemical profiling and energy dispersive spectroscopy with multiple detectors. (EDS) for phase mapping of the material.

Masic also co-authored a 2021 study that analyzed samples of the ancient concrete used to build a 2,000-year-old mausoleum along Rome’s Via Appia known as the tomb of Caecilia Metella, a noblewoman who lived in the first century AD. . It is widely regarded as one of the best preserved monuments on the Via Appia. They used the advanced light source to identify the many different minerals in the samples and their orientation, as well as scanning electron microscopy.

They found that the tomb’s mortar was similar to the walls of Trajan’s Markets: volcanic tephra from the pyroclastic flow Pozzolane Rosse, binding large chunks of brick and lava aggregate together. However, the tephra used in the tomb’s mortar contained much more potassium-rich leucite. The potassium in the mortar, in turn, dissolved and effectively reconfigured the binding phase. Some parts remained intact after more than 2,000 years, while other areas looked wispy and showed signs of splitting. In fact, its structure somewhat resembled nanocrystals. So the border zones are constantly evolving through long-term remodeling, strengthening those border zones.

For this latest study, Masic wanted to take a closer look at strange white mineral chunks known as “lime clasts,” which others had largely dismissed as the result of substandard raw materials or poor mixing. “The idea that the presence of these lime residues was simply attributed to poor quality control always bothered me,” says Masic. “If the Romans put so much effort into making an excellent construction material, according to all the detailed recipes optimized over many centuries, why should they have put so little effort into ensuring the production of a well-mixed final product? ? There has to be more to this story.”

It was believed that the Romans combined water with lime to make a highly chemically reactive paste (quenching), but this would not explain the lime clasts. Masic thought they might have used the even more reactive quicklime (possibly in combination with slaked lime), and his suspicion was born from the lab’s analysis with chemical mapping and multi-scale imaging tools. The clasts were different forms of calcium carbonate, and spectroscopic analysis showed that those clasts had formed at extremely high temperatures, known as hot mixing.

“The benefits of hot mixing are twofold,” Masic said. “First, when the total concrete is heated to high temperatures, it enables chemistry that isn’t possible if you just use slaked lime, producing high-temperature-associated compounds that otherwise wouldn’t form. Second, this elevated temperature curing and curing times significantly as all reactions are accelerated, allowing for much faster construction.”

It also seems to give self-healing abilities. Per Masic, when cracks begin to form in the concrete, they are more likely to move through the limestone creeks. The clasts can then react with water, creating a solution that is saturated with calcium. That solution can either recrystallize as calcium carbonate to fill the cracks or react with the pozzolanic components to strengthen the composite material.

Masic et al. found evidence of calcite-filled cracks in other samples of Roman concrete, supporting their hypothesis. They also created concrete samples in the lab using a hot mixing process, using ancient and modern recipes, then deliberately cracking the samples and running water through them. They found that the cracks in the samples made with hot-mixed quicklime healed completely within two weeks, while the cracks never healed in the samples without quicklime.

DOI: Science Advances, 2022. 10.1126/sciadv.add1602 (About DOIs).