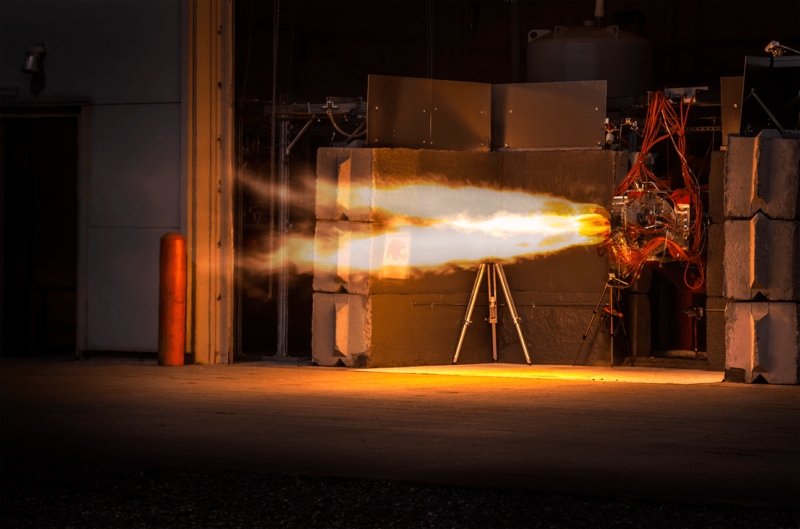

Startup Ursa Major announced on Wednesday that it had completed qualification of its Hadley rocket engine for use by both a space launch vehicle and a hypersonic launch system. The Colorado-based company said it has already started supplying flight-ready Hadley engines to two customers, Phantom Space and Stratolaunch, and plans to produce a total of 30 engines this year.

The Hadley engine is relatively small as rocket engines go, with about 5,000 pounds of thrust. At that level of performance, the Hadley is comparable to Rocket Lab’s Rutherford engine, nine of which power the first stage of Rocket Lab’s Electron rocket.

In his announcement, Ursa Major praised the versatility of the Hadley engine in two very different environments. Phantom Space is developing its Daytona rocket as a small lift booster, using seven Hadley engines in the first stage to lift up to 450kg to low Earth orbit. A single, vacuum-optimized Hadley motor will power the upper stage. Phantom says it is booking launches for 2023.

Stratolaunch, on the other hand, built the world’s largest aircraft, with a wingspan of 385 feet (117 m). Known as Roc, the aircraft recently completed its fourth test flight, reaching an altitude of 15,000 feet (4.6 km). This massive aircraft carrier will be used to launch the rocket-powered Talon-A hypersonic vehicles, which will serve as a testbed for hypersonic research. Stratolaunch plans to begin flight testing this year and begin offering commercial and government services by 2023.

Multiple applications

“It’s been quite difficult,” Joe Laurienti, founder and CEO of Ursa Major, said in an interview with Ars about developing such a versatile rocket engine. “When you’re focused on a single mission, you’re focused on a single application. You adjust very closely the things that can go wrong on the bike you have to work out.”

Because it is intended to serve multiple users, the Hadley engine has undergone significantly more test time, about 40,000 seconds to date. It has been tested in air-launch simulations, for multiple reboots, deepthrottling and more. “You’re trying to simulate a lot more problems that the engine has to endure and survive than a single mission or a single launch application,” Laurienti said.

Having previously worked on the Merlin rocket engine at SpaceX and the BE-3 at Blue Origin, Laurienti founded Ursa Major in 2015. He saw many start-ups, but felt there was a niche for a company that focused purely on propulsion. His company decided to start with a smaller engine (because small engines were economically viable) and grow from there. The Hadley engine now has multiple customers — the Air Force’s X-60A is another — and Laurienti said interest is high.

Laurienti said his sales pitch when meeting potential clients is simple. “Having an engine off the shelf saves you five years or more,” he said. “It’s also probably going to save you $100 million. So that’s usually a quick, quick call.”

Ripley too

With Ursa Major, Laurienti has tried to keep engine costs down by using mass-market 3D printers and by keeping a relatively low workforce. The total number of employees at the company only recently surpassed 200. To date, Ursa Major has raised approximately $140 million.

And while Ursa Major started small, the company is already well into the development of its much larger Ripley engine. With a thrust of 50,000 pounds, Ripley targets the medium-launch market.

“We see Ripley coming to market here in the coming years with a number of partners,” said Laurienti. “And then there will definitely be another engine program in the pipeline that we’re not really talking about yet, but hopefully pretty soon.”

At that point, Laurienti should have some idea if the market is really ready to support a commercial space company dedicated solely to liquid rocket engines.