There’s rarely time to write about every cool science story that comes our way. That’s why we’re posting a special Twelve Days of Christmas series of posts again this year, highlighting a scientific story that fell between the cracks in 2022 every day from December 25 to January 5. Today: Researchers discovered how to cook tasty popcorn with infrared.

Most of us rely on air poppers or microwave ovens to make a tasty popcorn snack. But infrared cooking offers another viable alternative, according to a September paper published in the journal ACS Food Science and Technology.

Popcorn is the only grain in the corn family that pops in response to the application of heat, especially temperatures above 180 degrees F. It has a lot to do with the structure of the grains. Each has a tough outer shell called the pericarp, which contains the germ (seed embryo) and endosperm. The latter contains trapped water (popcorn kernels need about 14 percent water to pop) and starch granules.

As the kernel heats up, the water in the endosperm turns into superheated steam, increasing the pressure in the pericarp. When that pressure gets high enough, the pericarp ruptures, releasing the steam and starch into a froth, which then cools and solidifies into the snack we know and love. A popped kernel is 20 to 50 times larger than the original kernel.

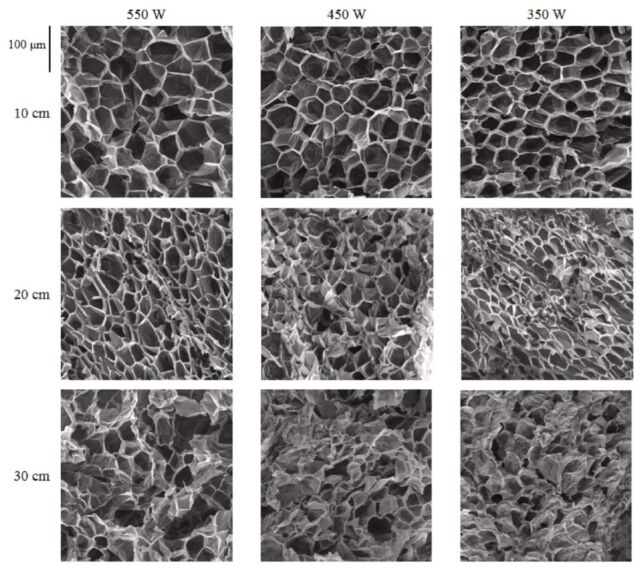

M. Shavandi et al., 2021

Last year, Mahdi Shavandi and his co-authors at the Iran Research Organization for Science and Technology in Tehran successfully demonstrated the proof of principle for their approach to making popcorn using infrared heat. In this method, a heat source such as fire, gas or energy waves is in direct contact with the food, rather than a heating element such as a pan or grill grate. It is often compared to roasting or cooking food over a campfire. Fans claim that this method is fast, very energy efficient and environmentally friendly compared to more conventional heating methods.

According to the authors, it is already used for purposes such as heating, drying, frying, cooking, baking and even microbial decontamination. And infrared grills are becoming more and more popular. But could you use infrared cooking to produce popcorn with all the desirable characteristics we know and love, and convince us to switch from our beloved microwavable brands? Shavandi et al. thought it would be possible.

They placed popcorn kernels – harvested in Iran during the 2019-2020 season – in a pyrex petri dish with a little oil in a stainless steel chamber, which was equipped with two infrared lamps and a power supply. The chamber rotated, holding the corn kernels close to the infrared lamps. The popcorn was then popped, removing any unpopped samples. The scientists measured the yields and took SEM images of the popcorn to get a closer look at its structure. They found that the highest bang output (100 percent) and volume expansion occurred at 550 W IR power, with the samples placed 4 inches (10 cm) away from the lamps.

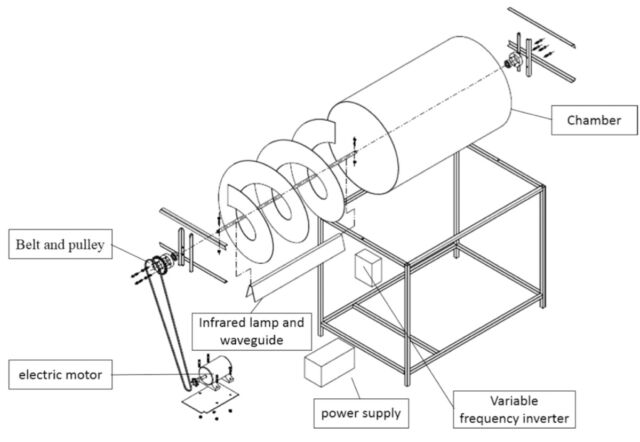

M. Shavandi et al., 2022

But would consumers like it? This latest article follows up on that proof-of-principle to take a closer look at how the continuous infrared cooking process affects popcorn’s key characteristics: color, shape, smell, taste, and texture (which is affected by how much the popcorn expands), all of which contribute to the sensory pleasures of popcorn. They used the same infrared popcorn popper prototype as before for their experiments, testing power levels of 600, 700, and 800 W. Then a sensory panel of taste testers evaluated the final products on a scale of 1 to 5.

The team found that using 700 W of power produced the highest yield of fully or half popped popcorn. That power level also produced the highest ratings (4 or higher) by the sensory panel, which identified those batches as having the best color, flavor, and firmness. “This is the first study of the continuous infrared expansion technology for popping popcorn, and the findings show that the IR expansion method is highly efficient in the popcorn popping process,” the authors conclude. So maybe our kitchen gadgets will include an infrared popcorn popper in the near future.

DOI: ACS Food Science and Technology, 2022. 10.1021/acsfoodscitech.2c00188 (About DOIs).