Getty Images

The human love affair with whipped cream dates back to at least the 16th century, and it’s a staple of all of our favorite holiday desserts. Is that slice of Thanksgiving pumpkin pie really the same without a dollop of whipped cream on top? But whipped cream also contains 38 percent saturated fat. That’s one of the reasons why it’s so airy and delicious to eat, but it’s also not good for our health, and dairy farming is a major source of greenhouse gases. That’s why food scientists at the University of Copenhagen decided to investigate possible low-fat, sustainable alternatives. They successfully created a fat-free prototype based on bacteria, according to a recent article published in the journal Food Hydrocolloids. One day, according to the authors, the whipped topping on our holiday desserts could be made from beer brew leftovers or plants.

“We usually associate bacteria with something to keep away from food,” said study co-author Jens Risbo, a food scientist at the University of Copenhagen. “But here we are basing a beloved food product on good bacteria found in nature. This has never been seen before. This is beneficial both because it is a renewable resource grown in a tank and because it creates a healthier, less energy-dense, fat-free product.”

Whipped cream is a type of liquid foam, a category that also includes hair styling mousse and shaving cream. Such foams are made by whipping air into a liquid formula that contains, among other ingredients, some type of surfactant (active surfactant) – a collection of complex molecules that link together to stiffen the resulting foam into a substantial lather. The surfactant—usually fats or proteins in edible foams, or chemical additives in shaving cream or styling mousse—stops the surface tension of collapsing bubbles by strengthening the thin liquid film walls that separate them. Cream, with its high fat content, serves as a surfactant in whipped cream.

In 1948, a clothing salesman turned entrepreneur named Aaron (“Bunny”) Lapin figured out how to deliver whipped cream from a can and introduced the world to Reddi-Wip. Gas is mixed with the liquid formula and packed under pressure in the aerosol can. When the valve is opened, nitrous oxide (laughing gas) propels the mixture out of the can and the gas quickly expands to form foam. In non-dairy varieties of Reddi-Wip, the cream is replaced with vegetable oil, which has an even higher fat content, along with a range of synthetic additives (polysorbate 60, sorbitan monostearate, sodium stearoyl-2, lactylate, xanthan gum, and lecithin).

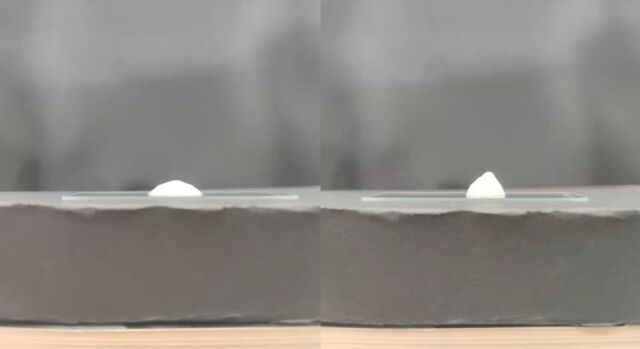

Xiaoyi Jiang et al., 2022

It’s not easy to come up with a tasty yet healthy alternative to one of our favorite treats. “The hardest part of developing an alternative food is getting the right texture,” says Risbo. “Whipped cream undergoes a unique transformation that takes place in a complex system in which a high saturated fat content makes it possible to whip the whipped cream stiff. So how do we create an alternative that avoids the high fat content and still achieves the right consistency?” ? Here we have to think innovatively.”

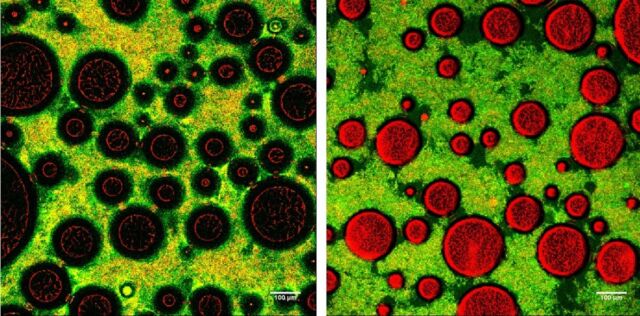

Risbo and his colleagues used only four ingredients in their experiments: water, edible lactic acid bacteria, a small amount of milk protein and a thickener. There are many types of lactic acid bacteria — the kind used by the food industry as a yogurt culture and to preserve processed meats — and they are abundant in nature, found in plants and in human and animal mucous membranes and digestive tracts. They also appear to be ideal building blocks for foodstuffs and are about the same size as the fat globules in heavy whipped cream.

The Danish team made both soft and stiffer versions of their prototype whipped cream using two different types of bacteria: Lactobacillus delbrueckii subs. lactis (LBD) and Lactobacillus crispatus (LBC). The LBC strain is more hydrophobic and produces a cream that is stiffer and holds liquid better than the brew produced with LBD, which is hydrophilic.

Xiaoyi Jiang et al., 2022

These experiments were primarily designed to prove the concept, and the resulting foams were judged primarily for texture and desirable foam properties – not taste. So it is not likely that we will see canisters with “Lacti-Wip” on store shelves anytime soon. But the experiments did provide valuable insight into how best to make a non-dairy whipped cream alternative with a similar food texture.

“We’ve shown that bacteria can be used to create the right structure,” says Risbo. “Now that we understand the context and have learned which surface properties are important, it opens up the possibility of using many other things from nature. These could be leftover yeast from brewing, or maybe small building blocks that we extract from plants. This would make the product very durable.”

DOI: Food Hydrocolloids, 2022. 10.1016/j.foodhyd.2022.108137 (About DOIs).